Investigation by Michael Hamm and Christian Hinterwaelder

Good lighting requires a good headlamp, well aimed. This investigation looks at the effect on headlight aim of individual tolerance contributors from car body parameters like load, tire pressure, suspension as well as temperature parameters of chassis and plastic parts.

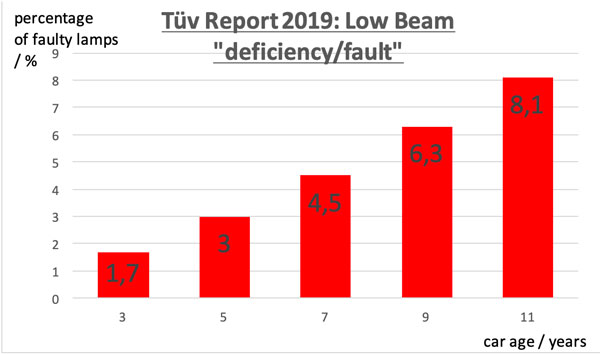

First, the main result from Germany’s TÜV. This is the official data of defects that are registered during the bi-annual roadworthiness inspection cars must pass; any defects found must be fixed before the vehicle’s registration can be renewed.

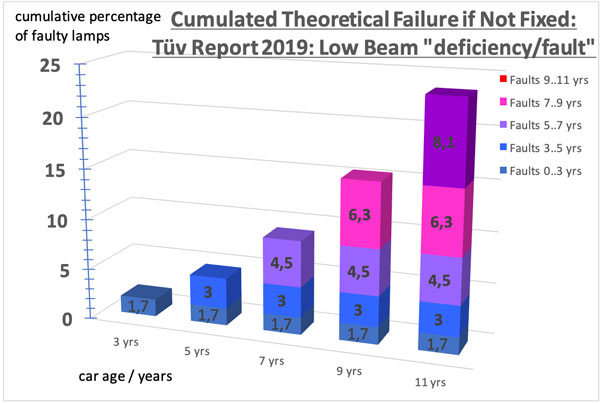

After each inspection, each car starts at zero defects. The paper makes a theoretical approach: What happens if there is no zero?

Low beam faults in cars from 3 to 12 years old are at 23.6%. This is reported as a theoretical maximum.

Repair might also be initiated by the car owner. It might also happen that the faulty low beam is generated by a dead bulb that could easily be replaced, etc.

So in countries without regular inspection, the realistic defect numbers are between the TÜV numbers and the cumulated theoretical maximum.

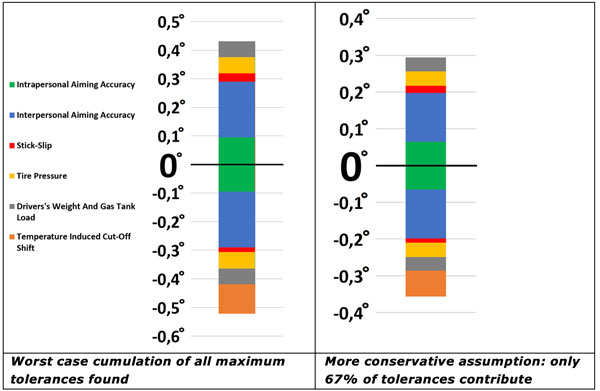

In a second part, the investigation analyses the tolerances in cutoff position during operation, from many different contributors including inter- and intrapersonal aiming accuracy, stick-slip effect, tire pressure variation, temperature load, driver weight, and fuel tank filling.

The investigation shows in the chart above that the headlight aim in a used car can fluctuate in a conservative cumulative scenario about ±0.3°.

There are tolerances everywhere. There are many contributors to headlamp aim outside the optical and mechanical development targets.

The presented results show the variations in reality, but they are not fully explaining the TÜV Report results shown in the beginning of that paper. It seems very difficult to predict the real aiming variation by tolerances. The TÜV report reveals that aim variation is normal and needs to be controlled.

Additional effects like small accidents, ageing, lifetime related relaxation of the suspension systems and changes in car chassis or body in white relaxation have to be considered in future in order to come closer to a comprehensive picture and changes in car chassis or body in white relaxation have to be considered.

3 questions to Michael Hamm and Christian Hinterwaelder

Dr. Michael Hamm joined Audi in May 2012 as manager of headlamp development.

During his professional work he has contributed to 70 patent families and published more than 35 technical papers, interviews and publications.

Co-author Christian Hinterwaelder joined Audi in 2019 and works in headlamp development. His tasks also cover accident research and headlamp rating.

DVN: Do you have proposals to reduce the consequences of these tolerance contributors?

Christian Hinterwaelder: Biggest contributor is the human eye. Nobody should believe he is able to exactly identify a cutoff.

And some tolerances just apply from plus to minus during operation. Take the gas tank filling: Full tank means higher aiming than empty tank. So the surrounding conditions must be kept in full control and we need better aiming machinery. Especially we need an optical precision better than our human eye accuracy.

DVN : What technology of automatic aiming could solve the tolerance problem?

Michael Hamm: In this case a possible correct answer would be rocket science. No joke—in missiles there are precise 3D positioning devices; we should think on something similar adopted in automotive. A kind of triple gyroscopic determination of the headlamp coördinate system, the car coordinate system, and the street coördinate system. Then we would have perfect aim everytime and everywhere.

DVN: OK, but that would surely take a long time to perfect In the meantime?

M.H.: We must continue in small steps. Improve awareness, improve aiming. We should try to increase automatic levelling to reduce glare and increase ADB systems penetration because they are less influenced by vertical aiming deviations. Wherever possible, decrease tolerances and improve sensor ability. A very big milestone would be any kind of closed loop between the aiming and the resulting light distribution on the street. This is an important task, also for future digital projections on the road.