I took time during the last weeks to investigate the lighting package on planes. I had questions: is it something similar to vehicle lighting, do you have lighting and signalling functions, what is the needed range, what are the intensity requirements?

There are multiple lamps on a plane — 10 different functions as shown in the graphic here from Safran.

First, the ground-illumination lamps. The most powerful is the landing lamp, for take-off and landing. It puts out around 700 kcd peak intensity, with a 14°H × 9°W beam — similar beam shape to an old US high-beam sealed beam, but with much greater intensity. Before LED introduction, tungsten and halogen sealed beams and lamps were used, with a rated lifespan of perhaps 10 to 25 hours. Redundant lamps were needed to be sure the plane would have working light during take-off and landing. Redundancy has long been a core tenet of aeronautic engineering in general, and it applies also to lighting. Then halogen bulbs were replaced by HID technology similar to the D1S and D2S Xenon automotive headlight lamps.

700,000 candelas! That is equivalent to the flux of ten automotive high beams with Emax 100 lux. If we talk about power consumption, halogen power was around 600 watts, while LED lamps serving the same function are around 100 – 150 Watt. Thermal dissipation is crucial, of course, when developing a high-power, safety-critical lamp. What is the needed derating curve, how to dissipate heat and what are the environmental conditions to be face at different altitude from 0 to several dozens of kilometres, with speed from zero to Mach 2…!

Why 9 degrees vertical field of view on the landing light? this is to cover all the different pitch angles of the plane during take-off and landing due to speed and wind. There is no levelling system in these lamps like on cars with sensors and actuators to calculate and compensate for the pitch of the plane.

To fulfil environmental-degradation requirements (sun and sand), outer lenses are now mostly made of polycarbonate — like automotive headlamps, but with thermal coating, because UV coating isn’t sturdy or durable enough. This is also the case for most lidar covers, though some of those are still glass.

The next ground illumination function is the taxi light. This is for low speed, so the required intensity is less, but the beam is thrice as wide as the landing light, at 42° degree). This would be the equivalent of the automotive low beam.

Finally, there is the RTO (runway turn-off) beam. A rough automotive equivalent would be fog/cornering lamps. These are for the crew to see to the side when the plane is turning during ground manœuvres.

Then there are a plane’s signal lights, which can be readily compared to a road vehicle’s position and signal lights.

There are white forward and rearward strobe lights, with intensity at least 400 cd (like an automotive DRL). These are on the left and right wings, for collision avoidance. They flash with a certain pattern (50 ms ON – 1,400 ms OFF as an example). In addition, there’s a strobe at the rear of the plane.

Navigation lights, red to port (left) and green to starboard (right), advertise the position of the plane, and its direction of travel. Intensity is lower, around 20 to 40 candelas. The beam specifies a cutoff to avoid projecting light to the rear. These are quite directly comparable to a car’s white front and red rear position lamps, and its amber side marker lamps.

To reach the photometry requirement is sometimes not easy due to significant wing curvature. Optical rules for light transmission are similar for all optical engineers. Position of the lamps is crucial, and there must be loops between aircraft designers and lamp makers — just like vehicle lighting’s design convergence loops.

Then there’s the anticollision light. This red light is on the roof of the plane, and must produce at least 400 cd in red color, flashing. The highest-intensity red automotive lighting function, the rear fog lamp, requires only 140 cd. To obtain 400 cd minimum with red LEDs is not simple; it needs many LEDs and very effective thermal management.

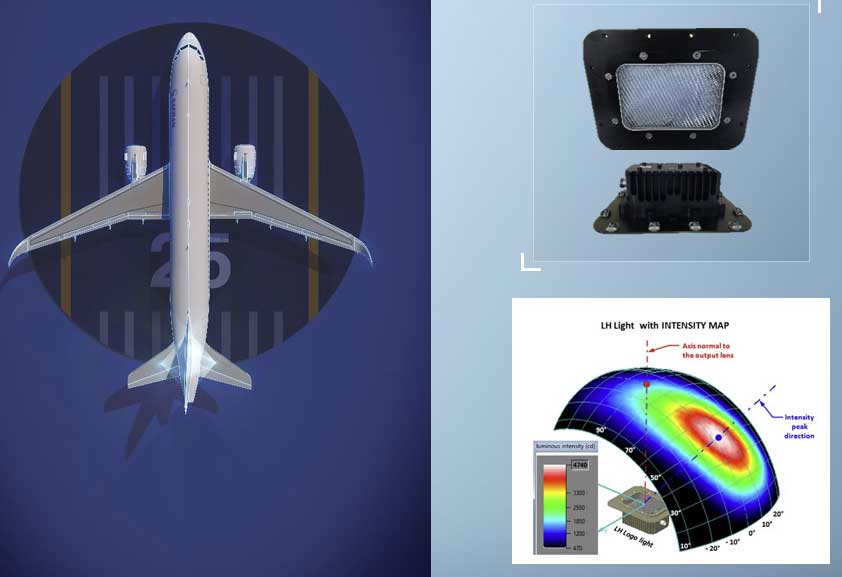

Finally, there’s the logo light. Mounted on the tailwings, it illuminates the tail number (comparable to a vehicle licence plate) and any logo on the fin. Due to the size of the fin and the location of the lamp, minimum intensity is quite high — 4,000 cd — so as to provide adequate luminance on the fin.

Beyond all these safety lights, other types of light exist as well, such as wing/engines lights (to check from the cockpit if everything is okeh), helicopter search lights (350,000 cd) for search and rescue, and more.

All these lamps must meet regulations — as automotive lamps must, but aircraft regulations are more stringent — and also customer requirements from the likes of Airbus, Boeing, and other plane makers. Certification is done by authorities: EASA in Europe, and FAA in the USA that delegate certification to aircraft manufacturers. What is different compared to automotive certification is that they are certifying also the development and production process, not only test results.

Environmental conditions are harsher compared to automotive. Plane lamps must meet military norms of -55°C rather than the automotive -40°C spec. Obsolescence is figured at 25-30 years, compared to 15 years in automotive. That can affect the supply chain, and there can be challenges when components like light sources or LED drivers become unavailable.

Another difference between airfaring and roadgoing vehicle lighting is the access of the final customer. They will never talk and listen with pilots (from the likes of Air France or Lufthansa or United or…) to know their habits, what lighting they would like to have, etc…not easy to know what the need for final customer is to optimize a new lamp development.

This global market is estimated at €100m per year, so it’s quite a niche market. The main tier-1s are Safran, Collins, Honeywell, Astronics, and Aveo.

Skills to develop plane lamps are similar to what we need for automotive. Photometrics tools to develop beam patterns…goniophotometers, luminance cameras, and for sure optical engineers.

One of the big activities is the LED retrofit to replace the filament lamps still in service on a lot of planes. The goals are the same as ours: to increase lifetime of the light source and end the need for frequent replacement. A central challenge is to reduce the price of the current aircraft, and to reduce power consumption for new aircraft development. In a very competitive environment with Chinese competition. All in all, then, they are living and working in a world similar to ours.